Application

Ball valve is isolating valve designed to fully open or

close the service fluid flow. It is not designed to be used for throttling or

regulating purposes. For temperatures from −50 °C to +300 °C.

Suitable for water, steam, gas, oil, crude oil, acid, alkali and other

liquids and gases with mechanical impurities – solid particles with

sizes not exceeding 5 mm.

Approved for fluids in groups 1 (hazardous) and 2 according to

2014/68/EU.

Production range

- DN 10 – DN 100, PN 16 – PN 160

- NPS ⅜″ – NPS 4″, Class 150 – Class 900

Characteristics

- floating ball,

- full bore,

- anti-static design,

- stem secured against release (anti-blow-out),

- double stem sealing,

- primary sealing between ball and seat:

metal-metal,

- double stem sealing,

- sealed with O-rings – NBR, EPDM, FPM (FKM), HNBR, FFKM.

Operation

- hand lever,

- hand wheel with worm gear,

- pneumatic actuator,

- electric actuator.

Connection to piping

- weld end (KM 9103.X-MF) – butt or socket

- flanged (KM 9108.X-MF) – EN, API, GOST

Compliance with standards

- European standards:

- EN 1983, EN 12516–1, EN 1092–1, EN 17292,

- EN 558–1 series 1 or not standardised, EN 12982 series 68,

- EN ISO 80079–36 (ATEX) – II 1G Ex h IIB T6…T1 Ga,

- American standards:

- API 608, ANSI B 16.5, ANSI B16.25,

- ANSI B 16.10 or not standardised,

- international standards:

Testing

- EN 12266–1, EN 12266–1, leakage rate A – zero

leakage,

- API 598, or acc. to API 6D – zero leakage.

Materials

- standard: S355J2, A350 LF2, 1.4541, 1.4571, 1.4034 (MF5), Stellite

6 (MFS),

- upon request: P265GH, 1.4306, 1.4462, 1.7335 , Stellite 12, and other.

Optional accessories, adjustments and services

- different face-to-face dimensions or end combinations,

- adaptation of face form (Groove, Tongue, Spigot, Recess, O-ring

groove, RTJ),

- connection for actuator according to ISO 5211,

- fire-safe design – fire resistance in accordance with EN ISO 10497

(API 607),

- heating jacket – for keeping the fluid liquid,

- lockable handle with a padlock,

- extended stem – e.g. for the reason of insulation of the valve and

pipeline,

- design according to TA-Luft or EN 15848–1,

- limit switches,

- documentation according to EN 10204 3.2,

- special adjustments according to customer requests,

- design according to standard NACE MR 0175 or ISO 15156 for fluids with

hydrogen sulfide (H2S),

- fully welded design,

- design for application in potentially explosive atmospheres according to the

directive 2014/34/EU (ATEX):

- I M1 Ex h I Ma,

- II 1G Ex h IIC T6…T1 Ga,

- II 1D Ex h IIIC TX °C Da.

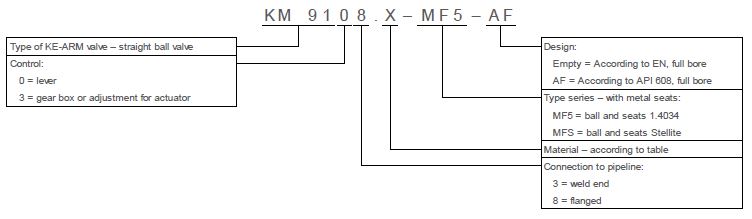

Type designation